Dyer Engineering, a manufacturer of metal components and welded structures, has been using Quuppa’s Bluetooth® based real-time location system (RTLS ) solution in its production facilities for some time. With ThinkIN location intelligence and asset tracking solution, the company monitors the movement of assets and goods, significantly increasing productivity.

At Dyer Engineering, different types of metals pass through several production areas. As many as 1,000 production orders are executed in the industrial facility at any time – each of them typically involving multiple operations. As a result, nearly 5,000 parts and components are in circulation simultaneously in the two production facilities. If parts and components are lost or misplaced, this can have far-reaching consequences, including:

- Severe production delays caused by an increase in the time required to get production processes up and running

- Work hours lost to manually searching for a misplaced asset within the facility

- Increased operating costs and a resulting decline in productivity

To address these issues on the shop floor, in early 2019, the metal manufacturer decided to implement an asset tracking solution for its production processes.

Requirements for the Real-Time Locating System

As part of a comprehensive tender process, the UK’s center for digital technology innovation, Digital Catapult, took a close look at a number of solutions for Dyer. The requirements for the future real-time locating system were high, including:

- Coverage/Cost Ratio: Due to the size of the installation, the necessary hardware and the associated costs were important factors. This is because the number of RTLS antennas that have to be installed strongly influences the costs for cabling and connectivity.

- Highest Accuracy: Since a large number of systems and components are moving on the shop floor at the same time, the position data of the objects had to have an accuracy of less than half a meter.

- Tracking a Large Number of Assets: The solution should be able to track up to 1,000 assets simultaneously and in real time, as well as provide extensibility.

- Readiness of the Solution: The system needed to be ready to go quickly and provide active monitoring, ongoing support, and maintenance. In addition, the development of detailed plans for the setup, configuration, and operation of the pilot project was desired.

![]()

FEATURED DOWNLOAD

Enhancing Bluetooth Location Services with Direction Finding

A new Bluetooth Direction Finding feature allows devices to determine the direction of a Bluetooth signal, thereby enabling the development of Bluetooth proximity solutions that can understand device direction as well as Bluetooth positioning systems that can achieve down to centimeter-level location accuracy.

Digital Twin of the Production Process

In the end, a solution that can track Bluetooth® enabled tags prevailed. The platform for a digital twin of the production process allows materials, goods, pallets, half-finished goods, and all other relevant assets to be located, tracked, and monitored within the factory in real time. It uses an RTLS system infrastructure to track Bluetooth Low Energy (LE) tags and applies the principles of Angle of Arrival (AoA) methodologies together with proprietary algorithms to provide highly accurate indoor location data.

…the savings amount to around £10 000 per month.

55 locators were installed in the two production facilities for this purpose. The production processes are tracked with a total of 1,000 tags. New production orders can be dynamically assigned to a tracking device (i.e. the tag) via a ThinkIN scan application. The ThinkIN data connectors are integrated with the Dyer ERP system, allowing basic information about a production order to be enriched with all the necessary data about the associated production process.

Significant Increase in Efficiency

The outcome is convincing; by implementing the asset tracking solution, Dyer Engineering is now able to spare an average of two labor hours previously used to manually search for assets. This translates into an efficiency boost of £10 000 per month (based on the 125 searches of the system to locate job orders). In addition, employees are now significantly more productive and efficient thanks to the ability to digitally locate assets using the ThinkIN platform. Currently, the system is being expanded to track and locate inspection fixtures at the end of the production line and further reduce lead times.

![]()

FEATURED INFOGRAPHIC

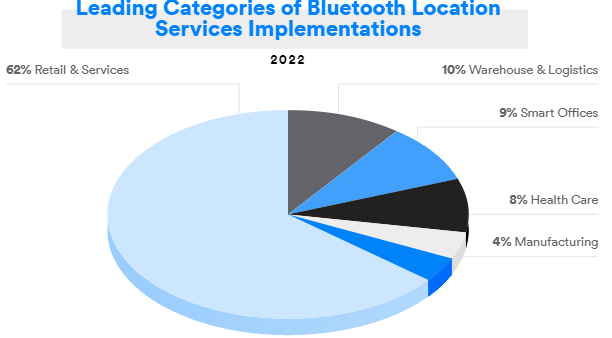

Bluetooth® Location Services Infographic

See 8 use cases for enhancing building efficiencies and creating a better visitor experience, discover new data that supports the latest trends and forecasts, and find out what’s driving the rapid adoption of location services solutions.

![ABI Growth Chart.png 815076338[1]](https://www.bluetooth.com/wp-content/uploads/2024/03/ABI_Growth_Chart.png_8150763381-660x384.png)